Recently, our company has made another good news in the bidding of the plant demolition project of Cangzhou Dahua Group Company. The project is located in the scope of the north plant area (former nitric acid workshop and hydrogen peroxide workshop) of Cangzhou Dahua Group. We would like to express our gratitude to the departments and colleagues who participated in this project for their hard work. In the future cooperation work, our group will do our best and always adhere to the spirit of "always struggle and go forward" to complete this project.

Cangzhou Dahua Group Co.

Cangzhou Dahua Group is a large comprehensive chemical enterprise group with fertilizer and TDI as its leading products, which is wholly state-owned by China National Chemical Corporation and Cangzhou Municipal Government. It has 6 subsidiaries (including 1 listed company) with annual production capacity of 360,000 tons of ammonia,580,000tons of urea,150,000tons of TDI,160,000tons of caustic soda, concentrated nitric acid and ammonium nitrate. In 2013, Cangzhou Dahua achieved a turnover of RMB 3.59 billion. Cangzhou Dahua, formerly known as the national-level enterprise - Cangzhou Chemical Fertilizer Plant in Hebei Province, was one of the first 13 large nitrogen fertilizer enterprises introduced and built in China in the early 1970s. It was one of the first 13 large nitrogen fertilizer enterprises introduced into China in the early 1970s to build complete sets of large fertilizer production plants from the United States and the Netherlands, which were reviewed by Chairman Mao and approved by Premier Zhou.

Cangzhou Dahua Co., Ltd. is one of the largest chemical fertilizer manufacturers in China, a national large-scale first-class enterprise and a large pillar enterprise in Hebei Province. The company passed ISO9002 quality system certification in 1998, which is the first in the industry. Meanwhile, in the national 863 computer information system project, it is the only enterprise in the national chemical industry with CIMS typical application project, which combines high-tech information technology with international quality management system.

We will apply the intelligent system of Haijiang Group in the process of dismantling Dahua Group. Haijiang's intelligent systems are as follows.

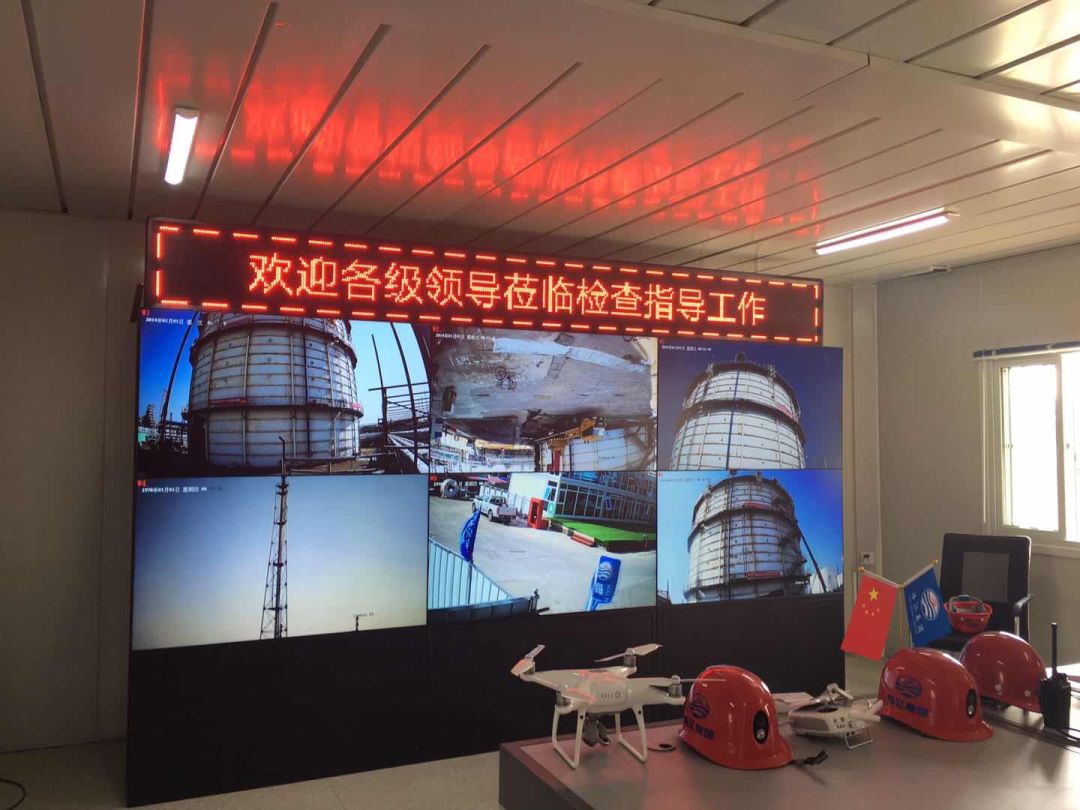

I. Intelligent monitoring center

The intelligent monitoring center of Haijiang Group monitors and guides the whole process of all demolition construction work surfaces on site, and screens and stores important information and data.

II. Intelligent Safety Helmet

Haijiang Group independently developed intelligent safety helmet, which has GPS positioning, real-time video monitoring, real-time voice communication, auxiliary lighting and many other functions, which is conducive to the group headquarters to more rationalize the control of the construction site.

III. Intelligent hydraulic shears

Intelligent hydraulic breaking shears were introduced in the demolition process. The construction process is dominated by machinery and supplemented by personnel. The site machinery is all equipped with monitoring system, real-time control of the mechanical demolition process, thus realizing the whole process of mechanical monitoring and management, maximizing the safety of construction personnel in the demolition process and achieving zero casualties.

Ⅳ. Intelligent firefighting robot

Advantages:

①No life damage: As a kind of inanimate carrier, the firefighting robot can give full play to its role when facing various dangerous and complex environments such as high temperature, toxicity, lack of oxygen and dense smoke, which greatly reduces firefighters' casualties.

② Reusability: As a special intelligent equipment, the firefighting robot can be used repeatedly and effectively while being carefully maintained.

③ Artificial intelligence: the firefighting robot can, according to the actual situation at the scene, independently determine the source of the actual dangerous situation, and carry out data collection, processing, transmission feedback, fire extinguishing and other work.

V. Load shift cold demolition process

Cold demolition technology (load shift) is a kind of demolition construction method that is directed and dumped at a fixed speed after making detailed measurements, analysis and positioning of parameters such as height, diameter and weight of the equipment, positioning slotting (or opening holes), and then using its own gravity and the push and pull of external machinery. This technology can be applied in the demolition process of large devices, towering towers, tanks, chimneys, etc., so as to improve the demolition efficiency.

VI. Intelligent drone cruise system

The difficulty of the China Shipping Petrochemical Project lies in the complexity of the demolition main body. Therefore, multi-dimensional detection is needed to ensure construction safety. The construction site has introduced an intelligent drone cruise system to achieve 360° multidimensional and all-weather monitoring.

The intelligent drone regularly inspects the construction site at high altitude, collects information on the high altitude work points and automatically transmits back to the management platform of information.

VII. Intelligent safety belt

It is used for monitoring the correct wearing behavior of the seat belt in the monitoring area, mainly including the safety monitoring of the leg safety buckle and high for low hanging. If there is unsafe operation behavior, the monitoring transmitting module will send the alarm information to the center client monitoring platform software or the cell phone APP of the person in charge.

Eight, water-based fire extinguishing agents