Sinopec Shanghai Petrochemical Co., LTD., together with Shanghai Emergency Management Bureau, Shanghai Fire and Rescue Corps and Jinshan District People's Government, jointly held a comprehensive fire rescue drill for Shanghai petrochemical equipment. Haijiang Group rescue Team was invited to observe and learn.

01 Shanghai petrochemical equipment fire rescue comprehensive drill resolutely shouldering the sacred responsibility of safeguarding national fire safety

Shanghai Deputy Mayor Zhang Xiaohong, Deputy Secretary-General of the Shanghai Municipal Government Xu Huili, Director of the Shanghai Emergency Management Bureau Ma Jianhong, Director of the Shanghai Fire Rescue Headquarters Liang Yunhong, Political Commissar of the Shanghai Fire Rescue Headquarters Wang Baoguo, Chairman of Shanghai Sinopec Co., Ltd. Guo Xiaojun, General Manager of Shanghai Sinopec Co., Ltd. Guan Zeimin, and Deputy Secretary-General of Jinshan District Liu Yunli attended the event and observed and guided the drill on the scene.

The comprehensive drill was held at Sinopec Shanghai Petrochemical Co., LTD. Sinopec Shanghai Petrochemical Co., Ltd. is one of the major integrated refining and chemical enterprises in China, as well as an important domestic production base for refined oil products, intermediate petrochemical products, synthetic resins and synthetic fibers.

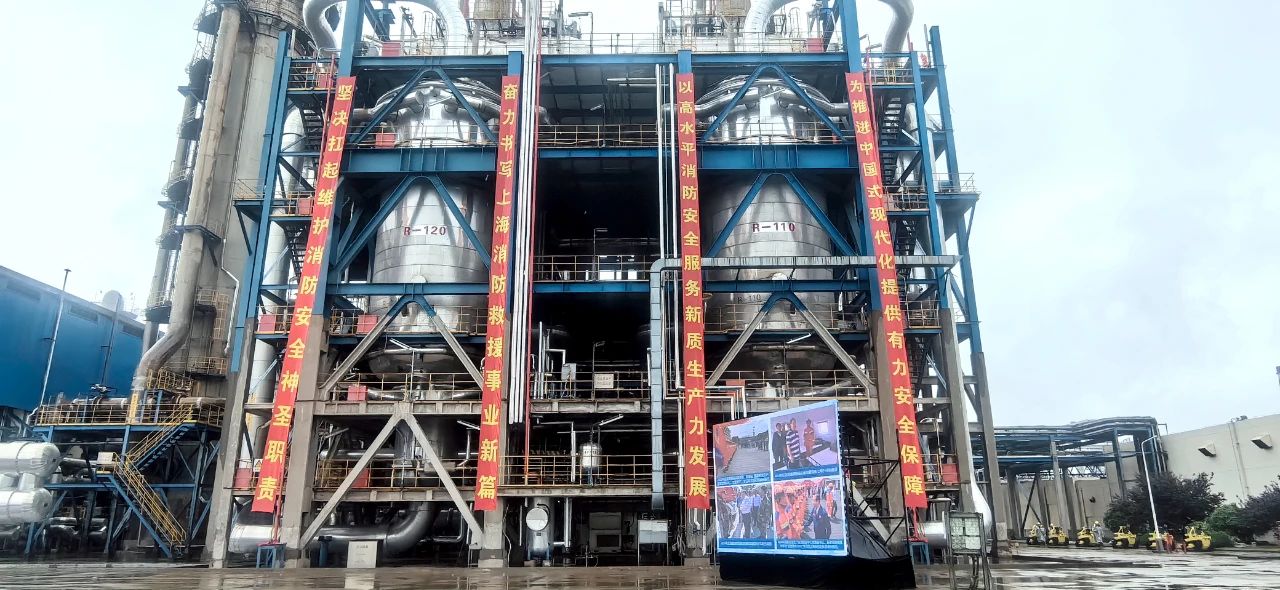

The drill object is a ethylene glycol production unit, which is composed of a reactor, a compressor, a refining tower, etc. Tower 1 is a contact tower, tower 2 is a refining tower, and tower 3 is a stripper tower. The installation area is 190 meters long, 82 meters wide, and 57 meters high at the highest point, with a total area of 15,580 square meters and a construction area of 380,000 square meters. The east side is adjacent to Xisan Road, the south side is Jin Yi Road, the west side is Xisan Road, and the north side is Hua Second West Road.

The disaster is set as the material valve due to the aging of the sealing gasket, a large amount of ethylene and methane leakage at the bottom of the reactor outlet, deflagration of combustible gas due to electrostatic fire, and overpressure explosion of the pipeline under fire baking. The explosion splash caused multiple fires in the storage tank, pipe gallery, and upper part of the reactor, accompanied by flowing fire.

The drill focused on the whole chain and process of fire disposal of petrochemical equipment, and set disaster scenarios such as flange leakage, pipeline deflagging, pipeline overpressure explosion, and multiple burning caused by explosion. The drill was divided into three stages: unit emergency plan drill, initial disposal drill of territorial fire fighting force, and cooperative disposal drill of fire fighting chemical formation. A total of 63 subjects were set up. Ten rescue teams, 90 vehicles and more than 300 people, including emergency, public security, medical, environmental protection, water, communications, meteorology and fire fighting, participated in the drill.

The first stage unit emergency plan drill

Scene setting: Flange leakage

Drill content:

Device control room emergency disposal, factory process disposal, emergency professional group disposal, fire alarm response, external road control

The second phase of territorial fire force initial disposal drill

Scene setting: Pipe explosion

Drill content:

Isolation warning, reconnaissance and detection, cooling and dilution, personnel search and rescue, water supply organization, safety control, communication guarantee.

The third stage of the fire chemical formation coordinated disposal drill

Scene setting: pipeline overpressure explosion, multi-point fire in the factory

Drill content:

Emergency avoidance, pipe gallery cooling, long transmission pipeline with pressure plugging, three echelon three superposition to fight flowing fire, robot formation fire fighting, public decontamination, tackling and closing valves, three-dimensional fortify, combat support, drone countermeasures, linkage disposal.

During the exercise, the participating units carried out disposal in strict accordance with the plan, showing excellent collaborative combat ability and efficient rescue level. Especially in the third stage, the fire chemical formation successfully dealt with complex fire situations such as pipeline overpressure explosion and multi-point fire in the plant area through collaborative disposal, demonstrating the important role of modern fire fighting technology in petrochemical fire rescue.

02 To provide a strong security guarantee for promoting Chinese-style modernization with the development of high-level fire safety services and new quality productivity

After the exercise, Zhang Xiaohong, Vice mayor of Shanghai, delivered a concluding speech. He said that the comprehensive fire rescue drill of Shanghai petrochemical plant is not only a test of Shanghai's actual combat ability to cope with and deal with petrochemical disasters, but also a test of the practical level of the overall fire rescue and emergency command system. The drill responded quickly, coordinated efficiently, and generally achieved the expected results. At the same time, Vice Mayor Zhang stressed three points:

First, we must put the people and life first, and resolutely shoulder the responsibility and mission of safeguarding people's safety and benefiting the people.

Second, we should put security first, give priority to prevention, and promote the transformation of security governance to prevention in advance. It is necessary to focus on the hidden risks and ideas in the petrochemical field, guide enterprises to strengthen risk identification, hidden dangers regulation and equipment elimination, promote the green, low-carbon and intelligent industrial upgrading of petrochemical enterprises, and effectively eliminate hidden dangers.

Third, it is necessary to forge a fire emergency team that is ready to be called upon and will win the battle. All departments should take this exercise as an opportunity to further do the three basic work of disaster prevention, disaster reduction and disaster relief in the field of fine petrochemical and hazardous chemicals, continue to optimize the emergency response mechanism, improve the emergency rescue plan, practice rescue and disaster relief skills, and constantly improve the comprehensive ability to combat disaster.

The high-quality development of regional emergency rescue is an important link to serve the development of new quality productive forces and promote Chinese-style modernization. Through this observation, the rescue team of Haijiang Group further learned the advanced petrochemical fire rescue technology and experience in Shanghai, and strengthened the understanding and cognition of relevant rescue scenes and tasks.

Looking forward to the future, Haijiang Group rescue team will take this opportunity to further strengthen the cooperation with the Shanghai Emergency Management Bureau and other rescue teams, use its own intelligent technology advantages, enable emergency rescue with 5G global remote unmanned control technology and AR reality intelligence platform, continue to enhance the breadth and depth of the use of unmanned mechanical rescue site, and adopt the new model of "smart emergency". Under the unified deployment of Shanghai Emergency Management Bureau, it serves the emergency rescue cause of Shanghai region, builds a solid safety base, holds the safety bottom line, and contributes to the high-quality development of Chinese modernization and the well-being of hundreds of millions of people.