On September 25, leaders of Xixian New Area visited Fengdong Modern Industrial Park for research and guidance, and leaders of Fengdong New City accompanied the research.

The inspection leading group first came to the intelligent dismantling center to understand the work plan of plant dismantling. Then they visited the intelligent command platform of dismantling dispatch and remote control platform. After questioning and discussion, they unanimously gave extremely high praise. Then they investigated the work progress in the main plant dismantling area, listened to the report on the dismantling process and safety measures, and gave important instructions on the intelligent dismantling project, requiring the dismantling work to be carried forward steadily under the premise of environmental protection and safe construction.

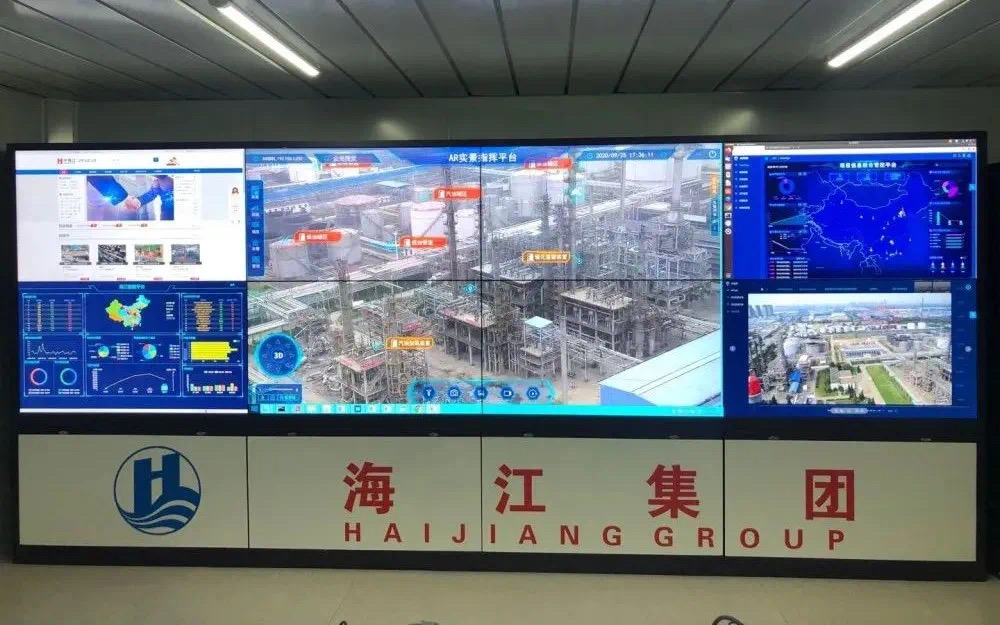

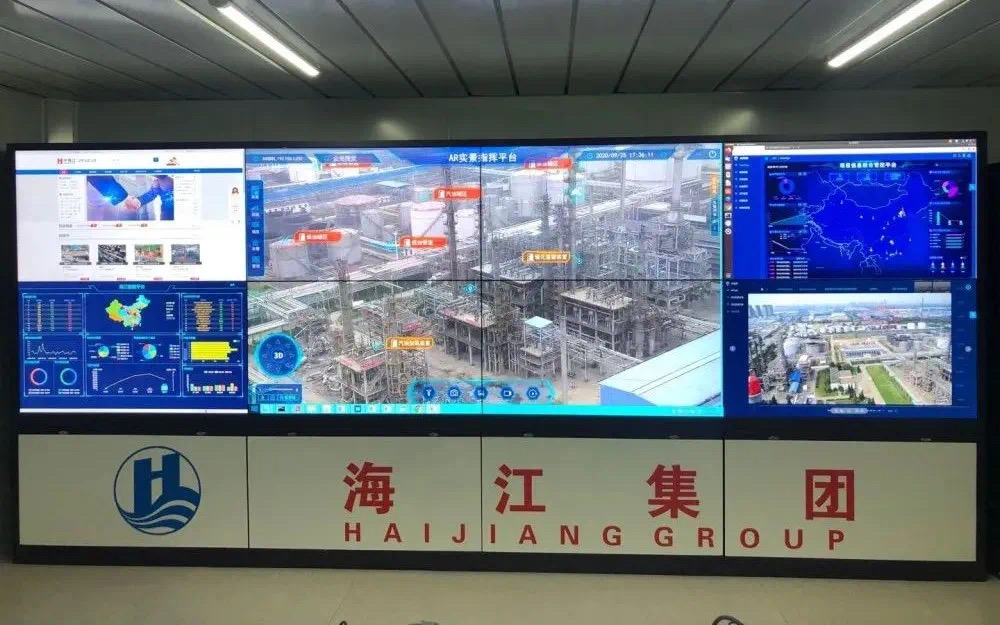

During the visit to the intelligent demolition command center, the team gained an in-depth understanding of the intelligent process system and integrated demolition solutions developed and applied by Haijiang Group. He was pleased and highly praised that Haijiang Group could apply 5G and AR technologies in the construction of Xi'an city. Mr. Liu Haijiang, Chairman of Haijiang Group, said that he would continue to coordinate and overcome difficulties to ensure that the demolition task would be completed with high quality and standard.

For this demolition project of Xi'an Petrochemical Plant, Haijiang Group used the company's unique 5G global remote control technology and AR real-world command platform to precisely command and dispatch during the construction operation, which can greatly avoid the operational risks of construction personnel, improve work efficiency and save labor costs.

5G global remote control

Cooperating with Huawei, the Group has achieved remote and accurate control of the operating machinery, making use of the characteristics of high-bandwidth and low-latency of 5G technology, clairvoyance and other core capabilities, combined with electronic control units(ECU), electric hydraulic converters, posture sensors,etc. which were self-developed by the Group. The operators can control the unmanned demolition machinery in demolition areas in real time in the remote control room, and simultaneously send back the real work scene video. This technology has a very high difficulty factor and is the first to be used in the same industry in China.

Using this kind of technology can effectively protect personal safety for operators in very harsh situations. It not only avoids operators from manipulating the equipment under high-risk and uncontrollable situation, but also breaks the drawbacks of the traditional demolition industry. It improves the working efficiency, saves a lot of labor costs for enterprises, and provides unlimited possibilities for the realization of intelligent unmanned sites in China.

AR real-view commanding platform

AR real-view commanding platform

Based on the AR camera's high-altitude bird's-eye view, all kinds of defense and control resources within the monitoring range are visually presented on a real-view map. Using 360°PAN/TILT and long-focus lens, it can form defense and control network with large view. With the combination of AR and AI, the commanding platform can support PIP video, support real-time alarm by AI intelligent algorithm, support the display of positioning devices in the video. Therefore, it’s absolutely possible to realize the visualization of the operator distribution, make full use of video, so that video data can really serve the management.

At the same time, the platform also has many application functions such as refined pre-program planning, precise warning, real-view command and dispatch, holographic scene retrieval, etc. It can provide digital management for a matrix of construction operators and comprehensive security plan of "holographic perception, unified pre-warning, intelligent linkage and precise command" for the project site.